top of page

All Work is Copyrighted Material and is Subject to Protection within its Ownership Rights.

At no point should any Material be shared without Approval or Consent from Ownership.

© All Rights Reserved.

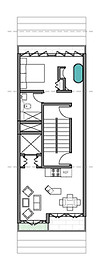

Efficiente

Big ideas For Small Lots

Type: AIA Competition Entry, Schematic Design

Status: Stakeholder Developement

113 W136th St.

bottom of page